course offer

PV Solar Training

Certificate in Rooftop Solar Project In rooftop solar sector a small entrepreneur needs a strong knowledge about off-Grid, On grid, hybrid system designing and financial benefit, bankable report preparation. This course will cover all aspect of designing and procurement, installation, financial modelling and customer nogotiation skills.

Certificate in Rooftop Solar Project In rooftop solar sector a small entrepreneur needs a strong knowledge about off-Grid, On grid, hybrid system designing and financial benefit, bankable report preparation. This course will cover all aspect of designing and procurement, installation, financial modelling and customer nogotiation skills.

Electric Vehicle Course

Certificate in Electric Bike and E-rickshaw Repairing E- bIKE AND E rickshaw repairing course you will learn the basic overview of electric BIKE AND E-rickshaw mechanism, how Electric 2W and 3W functions, what are the possible reason of failure and how you can repair them by your own, Troubleshooting of Motor, Controller and Charger faults.

Link Building SEO

5K Backlink Package

5K Backlink Package

All our backlink packages are a one-time fee and offering at a very competitive price. Backlinks we create are 99% do-follow links. Yes, you can submit your own blog content including YouTube / Video / Image URL if any.

Rooftop Solar Project Course

See More Popular Course

Electric Bike and E-rickshaw Repairing Course

See More Popular Course

5000+ High DR UR Backlinks

Search Low Cost SEO Services

All our backlink packages are a one-time fee and offering at a very competitive price. Backlinks we create are 99% do-follow links.Wednesday, December 28, 2022

Monday, November 28, 2022

LITHIUM-ION BATTERY FAILURE CAUSES

LITHIUM-ION BATTERY FAILURE CAUSES

LITHIUM-ION BATTERY FAILURE CAUSES

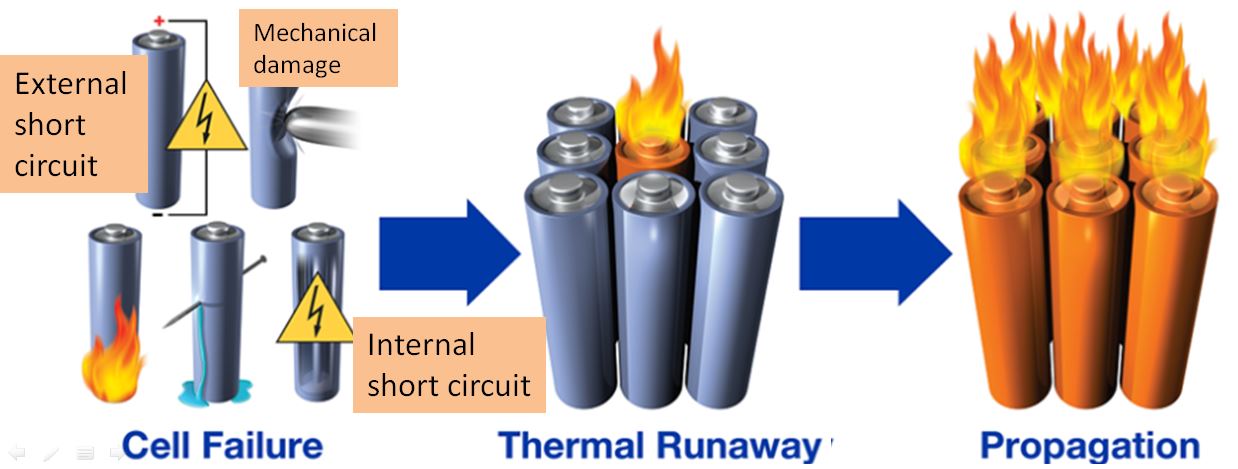

- External short circuit and cell failure

- Due to External pressure - Machanical damage

- Internal short circuit - due to chemical reaction, high C-rate or manufacturing faults

- Crush - by external cause - deformation of the cells

- Effects of internal short circuit due to - Dendrit growth, Separator damage

- Heat generation, Thermal abuse - Thermal Runway stage

As a crucial problem for the large-scale application of lithium-ion batteries, the safety issue attracts many concerns from consumers and manufacturers.

The failure mechanism is still unclear for some specific abuse behaviors, especially the damage evolution in cells or battery systems during the long-term operation. Based on the failure mechanism, some parameters and features can be used as signals for fault diagnosis and electric management. Safety designs in cells and battery systems can be employed to avoid more damage induced by abuse behaviors.

EV Battery pack assembly line course Topic are not limited to the items below, more related to battery failure mechanism and protection will be considered:

- Battery failure mechanism and modeling

- Safety design

- Fault diagnosis and prognosis

- Thermal and electric managements for better safety

- Advanced materials for improving intrinsic safety

Wednesday, November 16, 2022

degrade of battery pack cycle

battery capacity of tata nexon

maintenance cost of an electric car

electric car battery replacement cost

pillars of an electric mobility ecosystem

fame india scheme 2022

EVs components industry growth FY 2025

battery swapping companies in india

EV challenges and opportunities

EV business opportunities

business opportunities in electric vehicles sector in India

research opportunities in electric vehicles sector

multiple levels of vehicle electrification

sub system of electric vehicle

ICE common parts can use in EV drive train

EV braking systems

EV drive train parts

EV drive train parts to be added in EV

relationship between power and energy

battery technology crash course

lithium ion cells cathode and anode materials

six basic lithium battery

characteristics of lithium cell chemistry

lithium cobalt oxide LCO

lithium manganese oxide LMO

lithium nickel manganese cobalt oxide NMC

lithium iron phosphate LFP

lithium nickel cobalt aluminum oxide NCA

lithium titanate LTO

safer battery materials

indian li ion battery manufacturers

charge and charge capacity

li ion battery rated voltage and operating voltage

lithium ion battery self discharge voltage

factors affecting self discharge of lithium battery

lithium ion battery continuous current and peak current

lithium ion battery c rating

how c rate affects capacity fade

state of charge SOC and state of health SOH of the battery

state of power SOP

lithium ion cells internal resistance

life cycle and DOD relation of lithium ion cell

cycle life of li ion batteries

summery of battery degradation

maximum power point MPP of lithium ion battery

temperature window of lithium ion battery

degrade of battery pack cycle

causes thermal runaway

stage thermal runaway mechanism of lithium ion battery

internal short circuit in a lithium ion battery

lithium ion cell chemistry

cathode active material

cathode metal composition

anode active material

anion and cation

again review basic concept of anode and cathode

current collector at cathode side and anode side

advantages of aluminum foil battery

electrolyte allows the movement of ions

separator the absolute barrier between cathode and anode

solid electrolyte interphase SEI formation

lithium plating is a side reaction on the anode

dendrite growth causing internal short circuit

why dendrites form in li metal anodes

the effects of cycle rate at graphitic electrode

effect of high c rate

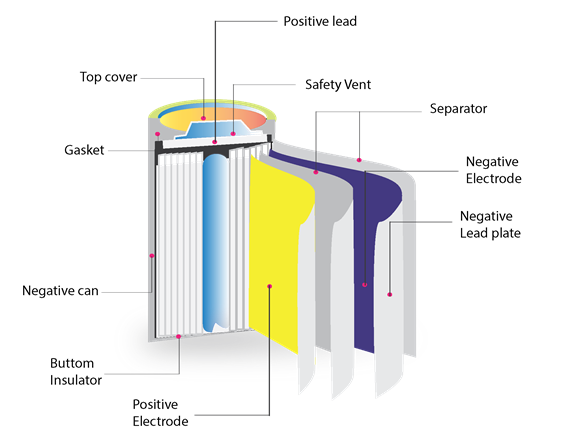

lithium ion cell architecture

lithium ion battery basic structure

cylindrical battery housing case

general requirements for packaging structures

anode negative plate

anode and cathode binders binders materials

lithium ion cell separator

lithium ion cell shutdown mechanism

lithium ion cell breakdown mechanism

lithium ion cell ceramic coated separator

positive electrode or the cathode materials

electrolyte cmpound

lithium ion cell protection vents

positive temperature coefficient PTC element

current interrupt device cid anti explosive valve

lithium ion battery thermal management

before battery pack design see

thermal runaway of battery pack

lithium ion cell temperature ranges

why thermal management is important

required functions of thermal design

low temperature effects on lithium ion cell

high temperature effects on lithium ion cell

how heat is generated in battery pack

effect of temperature on battery life

lithium ion cell internal resistance depend

battery thermal management systems BTMS

air cooling and heating system

liquid cooling and heating system

tesla cooling system configuration

direct refrigerant cooling and heating

phase change material PCM cooling

lithium ion battery battery management system

how can we define of li ion battery management system

cell balancing

active cell balancing

passive cell balancing

battery pack layout

battery pack design steps

battery pack assembly steps

battery pack cells configuration

mSnP battery pack

nPmS battery pack

calculations that are used in battery design

14s 6p pack using 21700 LFP cylindrical cell

li ion battery assembly line

assembly steps 1 cell sorting

cell capacity tester machine

insulation sticker pasting machine

mechanical design and packaging of battery packs

AC spot welding machine

DC spot welding machine

single side spot welding machine

double sides spot welding machine

auto laser welding machine

top five types of spot welding machine

BMS tester

welding bms to the battery pack

PVC heat shrink wrapping

battery pack comprehensive tester

battery aging cabinet

plant layout for lithium ion pack assembling

EV charging station site assessment

different type of EV charging system

charging station considerations

components of charging station

power flow diagram of level 3 and 4 EV charging

open charge point protocol OCPP

financial detail of charging station

proposed tariff for EV charging

on board charger for electric vehicles

charging current for lithium ion battery

factors that affect charging speed

public charging station PCS

site design guide line

turnkey construction for PCS

EV PCS site layout and execution

PCS foundation and cable raceway excavation

EV charging station electrical connection

charging station configuration

public charging infrastructure

financial detail of a PCS of 4 nos of charger

Monday, May 23, 2022

Friday, February 25, 2022

Li-ion Cylindrical Battery Fabrication

Step 1 Electrode Sheet Preparation

- Furnace: raw active material (Cathode & Anode)

- Milling Machine: grind & normalize the sintered material

- Mixer: mix active, conductive, and binder material into slurry under vacuum

- Coater: apply layer(s) of slurry onto current collector and dry it with an attached heater

- Rolling Press (calendar): compress the electrode to a desired thickness/density

Step 2 Cell Assembly

Winding Method

- Slitting Machine: slit/cut electrode sheet to strips of desired size

- Ultrasonic Welding Machine: joining of multi-layer electrodes, and/or tabs to collectors

- Winding Machine: form layers of Anode, Separator, and Cathode into a cell core

- Short-circuit Detector: test for integrity of the cell

- Vacuum Oven: remove any moister within the cell

Step 3 Case Sealing

- Spot Welding Machine: allow contact to be made from cell to bottom of case (grounding)

- Grooving machine: create indent on the neck of case to allow for proper seal (after inserting the cell core)

- Welding Machine: attach cell to cap (positive)

- Electrolyte Filling: inject the case with electrolyte under suitable environment within glove box

- Sealing Machine (Crimper): align cap with the open end of case and seal case inside glove box under suitable environment

- Recommend: wrap the newly finished battery with heat-shrinkable PVC for isolation of positive and negative terminals

- Battery Analyzer: charge/discharge the assembled battery for cell activation

Step 4 Battery Testing

Battery Analyzer to test the battery’s performance and Resistance Tester to measure battery’s internal resistance

Electric Vehicle and EV Lithium-ion Battery Training Courses

EV EVSE Business Management Course for Entrepreneurs

This Techno Commercial course: Throughout this training session, AEVT bridges the needs of startups so that candidate can understand the technology from basic of EV to EVSE equipment like Lithium-ion battery, Battery pack assembly process, EV Motor, Charger, charging station development and all others parts/ equipment's calculation, selection, building a Legal Foundation, Understanding Finance Basics, Business Planning and Fundraising.

Lithium Battery Pack Assembly course will cover li-ion cell to battery characteristic's, different parameters, EV battery Pack design aspect, calculation, assembly line unit detailing with financial aspects ,govt guidelines ,policies etc.

Electric Vehicle Charging Station Design, Installation

Consultancy Services

Saturday, January 1, 2022

Electric vehicle charging per kilometre 60 paise

The Ministry of Power has previously announced new EV charging infrastructure standards and guidelines. In compliance with the rules, the state government has fixed the ceiling cost of service charges to be charged by electric vehicle public charging stations. It approved the Rs 12.06 + applicable GST service cost maximum for electric vehicle rates covered by State/Central subsidies.

it is still less expensive than petrol and diesel. “It costs Rs 300 if any four-wheeler takes 25 units to completely charge their cars.” “You can’t even get three litres of petrol with the same quantity of petrol,”

Car comparison between petrol, diesel and electric vehicles

If the price of petrol is considered at Rs 100 per litre and mileage is considered 16 km per litre, the cost of the car, per kilometre, will be about Rs 6.25.

If the price of diesel is considered at Rs 95 per litre and mileage is considered 22 km per litre, the cost of the car, per kilometre, will be around Rs 4.31.

Whereas, an electric vehicle requires 30.2 units of electricity on being full charged, therefore if we consider Rs. 6 per unit as the electricity cost then it would cost Rs 181.2 for getting charged fully and then it would run for about 300km. In this way, its cost per kilometre will be close to 60 paise.

The cost of charging an electric vehicle (EV) in Mumbai would work out to Rs 15 per unit, according to the Brihanmumbai Municipal Corporation (BMC). As per their calculations, an electric car would take anywhere between 20 and 30 units to be fully charged and it would cost the user Rs 200 to Rs 400.

In Delhi, the government has fixed Rs 4.5 per unit for low tension charging of e-vehicles and Rs 5 per unit for high tension EVs. There would be a service charge based on the charging facility also. So it would cost anywhere between Rs 120 and Rs 150 for a fully charged EV.

As per the infrastructure guidelines set by the government, it is compulsory to set an EV Charging station at every 3km in cities and 25kms on Highways on both sides. For long-range and heavy-duty vehicles, there should be a charging station at every 100kms on both sides of the road (mostly Highways).

Cost of Setting Electric Charging Station in India

Cost of setting EV charging station in India varies from Rs. 1 Lakh to Rs. 40 Lakhs depending on the types of chargers and investment one is willing to make. However, considering a broader scenario and a supply of 250KVA EV Station below is the estimate.

| Charger Type | CCS – 60kW | CHAdeMO – 60kW | Type 2 AC – 7/22kW | Bharat DC-001 – GB/T | Bharat AC-001 |

| Approximate Cost | 12,50,000 | 12,50,000 | 1,00,000 | 2,40,000 | 60,000 |

- New Electricity Connection (250 KVA): 7,50,000 /-

- Civil Works: 2,50,000 /-

- EVSE Management Software + Integration: 40,000 /-

- Technicians, Manpower, Maintenance etc: 3,50,000 /- yearly

- Advertising and Promotion: 50,000 /-

- Land Lease (if the land is at lease): 6,00,000 /- yearly

Total Approximate: Rs. 40,00,000 /- (First year including setup and if the land is at lease)

Annual maintenance from the second year: Rs. 10,00,000 /- (Including land lease)

Minimum Infrastructure Requirement for EV Charging Station

- A transformer with subsequent substation must be installed along with safety equipment

- For the purpose of metering/ termination, there should be a 33/11KV Cable with related equipment.

- Appropriate Civil works should be there

- There should be adequate space for charging and Entry / Exit of Vehicles

- Necessary local certifications, if any required. (Varies state to state)

Understanding the Business (Revenue Model)

Revenue projections are something which we do not have control on. But we can assume a scenario and work out a feasible projection for the next 5 years.

If we take the above investment of Rs. 40 Lakhs, we get approximate of 500-1000 kWh per day EV power for consumption.